Tomorrow belongs to materials that deliver immense strength in a package so light it seems like magic. These composites revolutionize cars and planes. They’re making life faster, safer, and more efficient.

What Makes These Materials Special

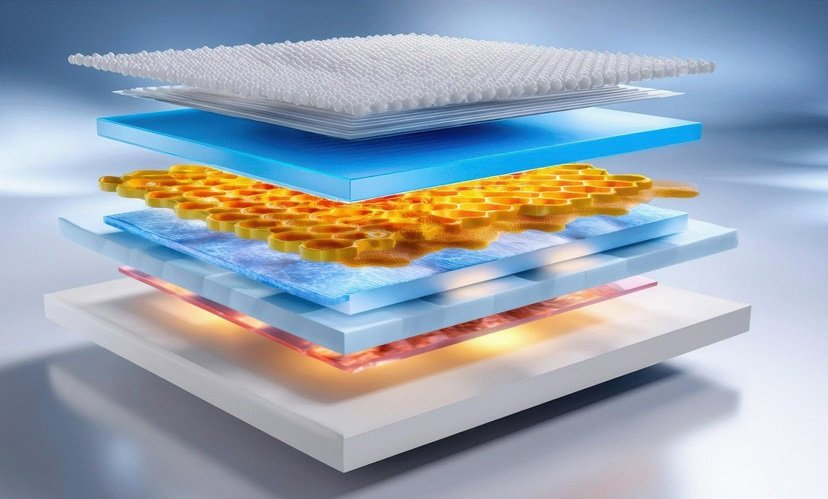

Old-school materials force engineers to pick a side: strength or weight. Steel is a tank, so it endures, but it drags extra mass wherever it goes. Aluminum soars in lightness yet it is at risk of cracking when things get harsh. New composites crush the dilemma by marrying the best characteristics of multiple materials into one overachiever. They begin with super-strong fibers, often carbon or glass. A specially engineered polymer is fused around them, locking everything in. The final sheet is lighter than aluminum yet tougher than steel, like a superhero in a business suit.

How They’re Made

Molding these marvels is a dance of precision. Skilled hands guide layers of fibers into precise patterns, like stitching a super-blanket one thread at a time. A new layer gets a different directional weave, each one fighting cracks and bends from every possible direction.

The good folk at Axiom Materials explain that composite prepregs push accuracy even further. These slices of fiber mesh come pre-impregnated with a precise amount of liquid resin. Craftspeople position them exactly where they’re needed, then pass the entire stack through heat to lock the shape. That level of repeatable duplication gives designers unmatched leverage over the finished part’s behavior.

Transforming Transportation

Vehicles are shedding excess weight while gaining fit-formed toughness. Racing teams discovered that carbon fiber bodies could protect drivers better than steel while weighing much less. Now regular cars use these materials in door panels, hoods, and even entire frames.

Airplanes benefit even more from lightweight composites. Modern jets use these materials for wings, body panels, and interior components. Passengers enjoy quieter cabins and smoother flights as a result.

Medical Miracles

Surgeons fit prosthetic limbs that feel much more natural. Thanks to its light weight and muscle sensors, amputees can move gracefully with confidence. A single thought can turn a hand, flex a knee, or twist a wrist.

Hospitals are celebrating longer-lasting knees and hips. The same materials that rescue skiers and soldiers now cradle new ball joints within cages that feel almost like warm muscle. Patients recover faster and return to active lifestyles sooner.

Environmental Benefits

Manufacturing with these materials often produces less waste than traditional methods. Composite parts are laid up in invisible, almost plotted layers that use precisely the slice of material a design insists upon. When the life is over, factories return any shard to the stew of new wind blades or automotive hoods.

Fuel-saving mathematics echo on the road, in the sky, and in every kitchen. Trim automotive frames, lighter train cars, and slender-winged airliners sip fuel, and every mile burned belies a smaller slice of soot. Buildings scarf smaller rises of summer heat and smaller drops of winter chill, sighing relief all the way to the power meter.

Conclusion

The arrival of lightweight, exceptionally strong composites is quietly rewriting the script of engineering and design. Visit a modern hospital and a hand-held sensor combines nanofibers and ceramics. Board a new-generation airline and the fuselage is a layered miracle of resin and carbon. Each leap was once visionary science but now it is an everyday facility. With smarter factories bringing prices within reach and printers, molds, and robots shrink further, possibilities multiply. Tomorrow will carry everyday goods and grand explorers alike with adventures in motion; ever lighter, decisively strong, and measured in carbon footprints the size of a whisper. This is the quietly breathtaking promise now within our reach, and the script will keep expanding.